We start by sourcing the highest quality natural fibers, including wool, silk, hemp and nettle from trusted suppliers. These materials form the foundation of our rugs, ensuring durability, softness texture.

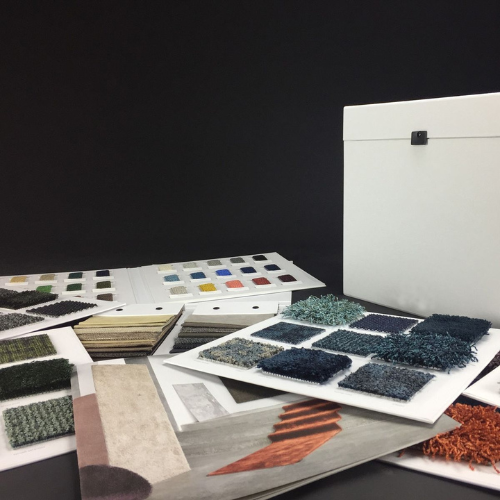

For trade and custom orders, samples or strike-offs can be developed prior to bulk production. Sampling allows buyers to review materials, colors, knotting, and finish before final approval.

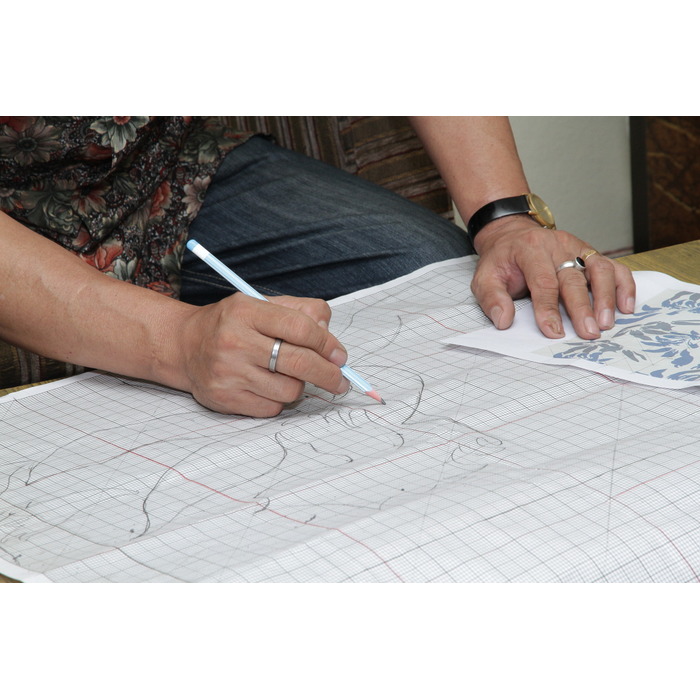

Our talented designers draw inspiration from diverse cultures, art forms, and nature itself. Every rug tells a unique story, with designs ranging from traditional motifs to contemporary patterns.

Our artisans carefully hand-dye the yarns using eco-friendly and AZO-free dyes. This process not only results in vibrant, long-lasting colors but also reflects our commitment to environmentally.

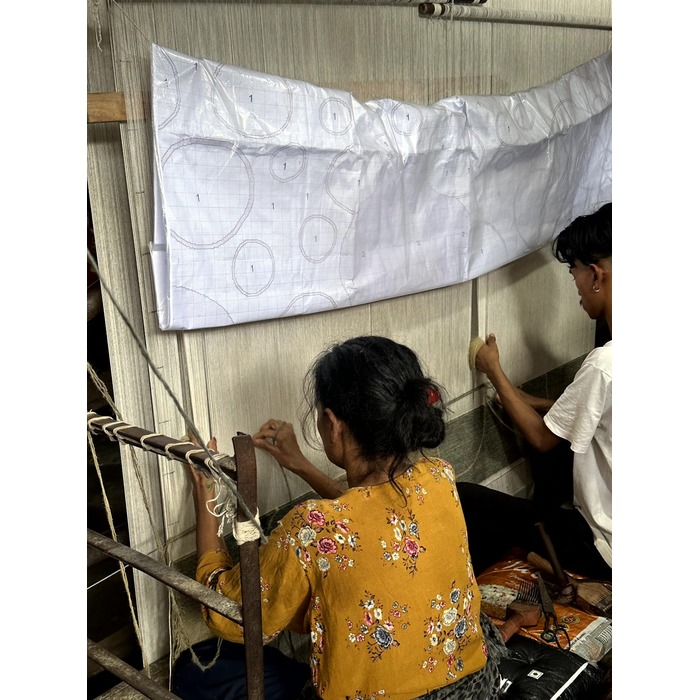

The weaving process is where the magic happens. Our skilled artisans meticulously hand-weave each rug, paying attention to every detail.

The finishing touches of a hand-knotted rug enhance its durability and beauty. Trimming evens the pile, washing brightens colors, and stretching maintains shape. Hand-carving adds depth, while binding or fringing secures the edges, ensuring a polished, long-lasting finish.

Rugs are packed according to export standards to protect them during international transit. We work with buyers to coordinate shipments under agreed Incoterms (FOB / EXW). Final shipping arrangements are aligned with buyer-appointed freight partners.

Share your project details, quantities, and design requirements to begin the sampling and production process.

The Hattu Rugs. Copyright © 2025.